Filter Paper Used in Electroplating Industry

Filter Paper Used in Electroplating Industry Specification

- Efficiency (%)

- 99%

- Diameter

- 100 mm to 600 mm

- Resistance

- Acid and alkali resistant

- Capacity

- High dust holding capacity

- Usage

- Commercial

- Type

- Round and Sheet

- Material

- Cellulose fiber

- Product Type

- Filter Paper Used in Electroplating Industry

- Thickness

- 0.5 mm - 1 mm

- Color

- White

- Thermal Shrinkage

- <2%

- Working Temperature

- Up to 120C

- Application

- Electroplating filtration

- Shelf Life

- 24 months

- Packing Type

- Boxed or wrapped

- Odor

- Odorless

- Surface Texture

- Smooth

- Moisture Content

- 7%

- PH Range

- 1-14

- Filtration Precision

- 1 to 25 microns

Filter Paper Used in Electroplating Industry Trade Information

- Minimum Order Quantity

- 10 Pieces

- Delivery Time

- 1-7 Days

About Filter Paper Used in Electroplating Industry

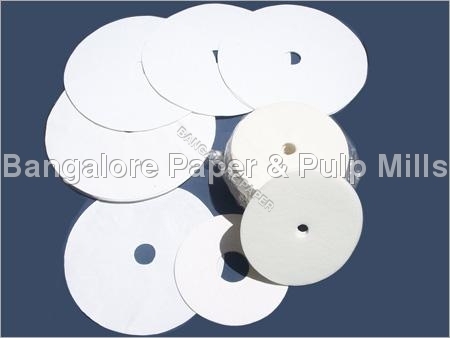

Circle Filter paper used for Electroplating Industry

We would like to introduce ourselves as the leading manufactures and suppliers of 100% Cellulose Filter paper and pads with an experience in this field for more than 25 years.

Since Cellulose Filter paper/Pads are of low ash content (approx 0.01%) and are non acidic reactive with any chemical or organic compound and also removes suspended particles in the electroplating bath . It is very safe in electroplating industry. The porosity is approximately 5 micron. The prices will be given as per your request.

BPPM Electroplating Filter is used in wide Applications-

Such as

Electroplating Bath

Plating Division

Sparkler Filters Etc

Since it is made of 100% Cellulose it can control micron from 1-100 micron

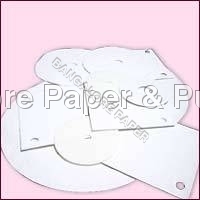

Avaliable in Roll, Sheet or Circle size

Exceptional Filtration Precision

Achieve reliable filtration performance with our filter papers precision range of 1 to 25 microns. This level of accuracy ensures high purity in electroplating solutions, which directly contributes to the quality and consistency of your finishes.

Engineered for Challenging Conditions

Designed to handle tough industrial environments, these filter papers are resistant to both acids and alkalis, and can withstand temperatures up to 120C. Their smooth texture and high dust holding capacity make them ideal for maintaining contamination-free electrolytes.

Versatility and Easy Incorporation

Suitable for commercial use in all types of electroplating filtration setups, our filter papers come in round and sheet formats, in diameters from 100mm to 600mm, fitting a wide range of filtration systems with ease. Their boxed or wrapped packaging ensures convenient handling and long shelf life.

FAQs of Filter Paper Used in Electroplating Industry:

Q: How does the filtration precision of this filter paper benefit electroplating operations?

A: The 1 to 25 micron filtration precision efficiently removes contaminants from electroplating baths, ensuring a clean electrolyte and resulting in smoother, higher-quality metal finishes.Q: What is the recommended process for using this filter paper in electroplating applications?

A: Simply install the filter paper, whether round or sheet, into your standard filtration unit. It is compatible with both continuous and batch systems and should be replaced when flow rates drop or upon reaching dust holding capacity.Q: When should I replace the filter paper in my electroplating system?

A: Replace the filter paper when you observe decreased flow rates, increased pressure differentials, or reduced filtration efficiency. Regular checks during maintenance schedules help ensure optimal performance.Q: Where can this filter paper be used within the electroplating industry?

A: It is suitable for use in a variety of electroplating filtration setups, including plating baths, rinse water treatment, and any stage requiring removal of fine particulates or chemical residues.Q: What are the advantages of the filter papers acid and alkali resistance?

A: The acid and alkali resistance ensures the filter paper maintains structural integrity and filtration performance when exposed to harsh chemicals commonly found in electroplating solutions.Q: How do I store the filter paper to maintain its shelf life?

A: Store the boxed or wrapped filter papers in a cool, dry area away from direct sunlight and moisture. Follow standard storage practices to preserve their 24-month shelf life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sparkler Filter Pads Category

Cellulose Filter Pads

Minimum Order Quantity : 100 Pieces

Color : White

Material : Other, Cellulose

Product Type : Cellulose Filter Pads

Usage : Commercial

Application : Water Treatment

PP Filter Bags

Minimum Order Quantity : 10 Pieces

Color : White

Material : PP

Product Type : PP Filter Bags

Usage : Commercial

Application : chemical, oil, gas and metal processing industries for filtering purposes.

Filter Paper

Minimum Order Quantity : 10 Pieces

Color : White

Material : PP

Product Type : Filter Paper

Usage : Commercial

Application : laboratory and industrial settings for various applications, including filtration, separation, and sample preparation.

Cotton and PP Filter Paper Pulp

Minimum Order Quantity : 100 Pieces

Color : White

Material : Cellulose

Product Type : Cotton and PP Filter Paper & Pulp

Usage : Commercial

Application : specifically for charcoal and activated carbon filtration.

GST : 29ADAPR8530P1ZU

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS